steel coil pendulum shear cut to length line about1650x3mm

1, Design from Taiwan Tengchi

2, Lot of casting, forged steel with strict QC work of each components

3, touched moving area insert copper plate to make it durable

4, all frame do quenching and tempering treatment

5, frame surface sand blasting

6, fast response and feedback of after sale services

1,coppergearinleveler 2, forged alloy steel roller

3, servo motor adjust leveler upper set and bottom set 4, Bottom backup roller adjust by 5 set motor

5,importedsportcontrolsystem 6, rotary shear blade gap adjustment by servo motor

7,advancedcontrolsystem 8, Camera video control system

9,highspeedline80m/min 10, factory direct supply

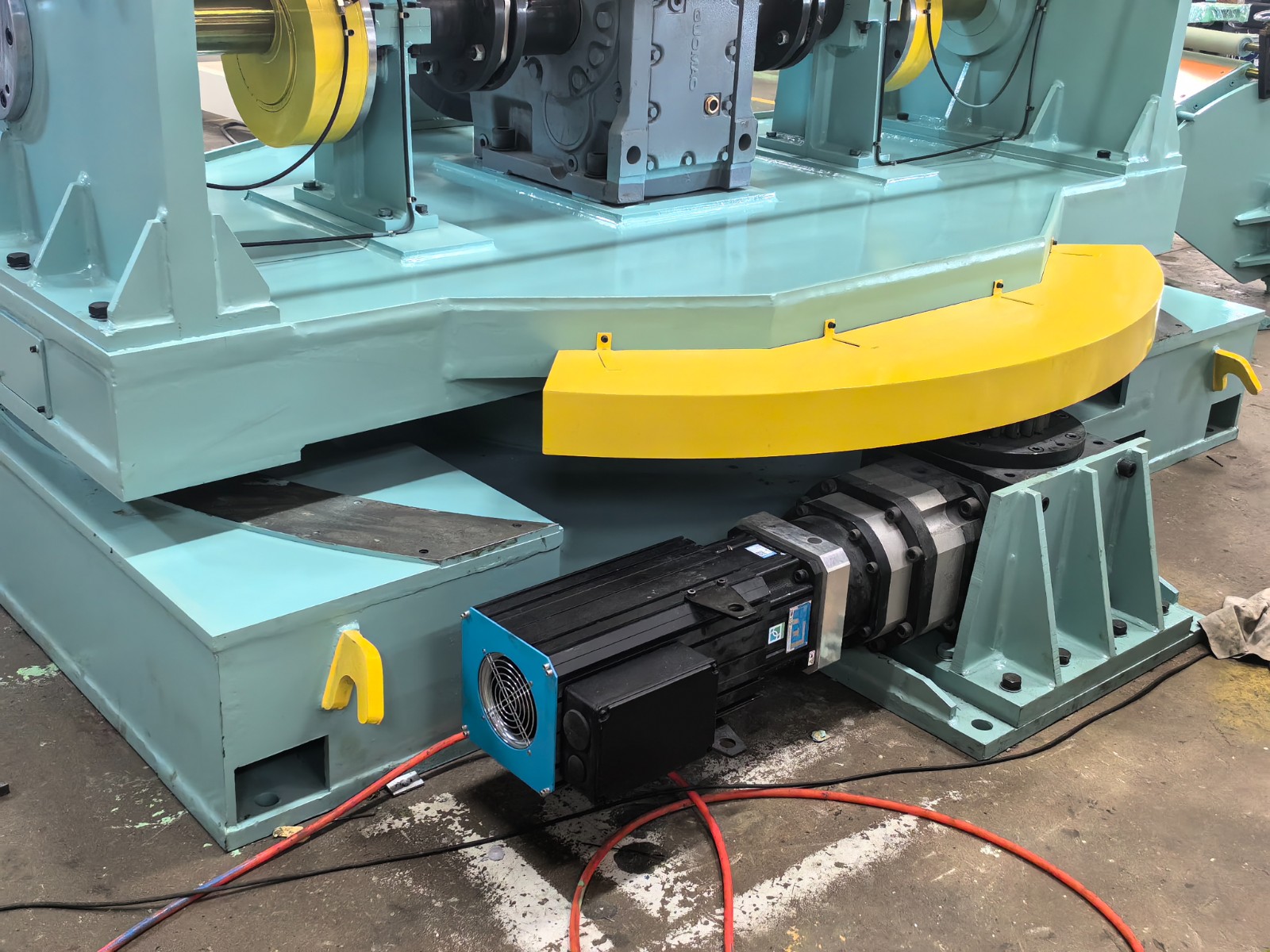

Coil To Sheet Cut To Length Machine

Line composition: Coil saddle---paper winder---coil loading car---hydro decoiler---pinch roll and 6 HI leveler---sizing feeder with PVC coater/paper coater---Stop shear---belt conveyor---stacker(1 sets)---hydro system---electric system

Machine parameters

1,Coilwidth:300-1650mm

2,Coil thickness: 0.3-3.0mm

3,Coilweight:25T

4,Line speed: 0-60m/min

5,Lengthaccuracy:+-0.3mm

6,Diagonal accuracy: +-0.5mm

7,Sheet length range: 500-6000

8,Sheet stacker height: 500mm

9,Stacker No:2 set

How we works for each component to handle the line quality of cut to length line

1, process the main components by our CNC machine that imported from USA

2, Main shaft choosing forged 42CrMo alloy steel to strengthen its mechanical ability

3, High speed feedback of services.

4, Advanced electric control system, Only one netwire out from main cabinet

5, Heavy steel body with tempered and quenched then sand blasting to remove surface oil and rust